Soft reactive metal used in magnets – At the forefront of magnet technology lies a remarkable class of materials—soft reactive metals. These metals possess a unique combination of properties that make them indispensable for creating magnets with exceptional performance and diverse applications. Embarking on this exploration, we delve into the world of soft reactive metals used in magnets, unraveling their properties, applications, and the intricacies of their production.

Overview of Soft Reactive Metals Used in Magnets

Soft reactive metals are a class of metals that exhibit high reactivity and low mechanical strength. They play a crucial role in the production of magnets, particularly those used in electronic devices and industrial applications.

The unique properties of soft reactive metals, such as their high surface area and ability to form stable oxides, make them ideal for use in magnet production. These metals are often alloyed with other elements to enhance their magnetic properties and stability.

Role of Soft Reactive Metals in Magnet Production

- Enhance Magnetic Properties:Soft reactive metals improve the magnetic properties of magnets by increasing their coercivity, which is the resistance to demagnetization.

- Improve Stability:These metals form stable oxides that protect the magnet from corrosion and oxidation, ensuring long-term stability and performance.

- Reduce Eddy Currents:Soft reactive metals have low electrical conductivity, which helps reduce eddy currents within the magnet, leading to improved efficiency and reduced energy losses.

Applications of Soft Reactive Metals in Magnets

Soft reactive metals, such as iron, cobalt, and nickel, play a crucial role in the manufacturing of magnets due to their magnetic properties. These metals are commonly used in various industries, including electronics, automotive, and medical, owing to their ability to generate strong magnetic fields.

Electronics

In the electronics industry, magnets made with soft reactive metals are extensively used in motors, generators, and transformers. These magnets provide the necessary magnetic force to convert electrical energy into mechanical energy or vice versa. They are also found in speakers, headphones, and magnetic resonance imaging (MRI) machines, where they generate magnetic fields for sound reproduction and medical imaging, respectively.

Automotive

The automotive industry heavily relies on magnets made with soft reactive metals for electric motors, actuators, and sensors. These magnets enable the efficient operation of electric vehicles by providing the required magnetic force for propulsion and various control systems. Additionally, they are used in anti-lock braking systems (ABS) and stability control systems, where they contribute to enhanced safety and vehicle handling.

Medical

In the medical field, magnets made with soft reactive metals are employed in medical devices such as MRI machines and magnetic resonance spectroscopy (MRS) systems. These magnets generate powerful magnetic fields that allow for detailed imaging and analysis of the human body, aiding in medical diagnosis and research.

Moreover, they are used in magnetic resonance therapy, where they generate magnetic fields to stimulate tissue healing and reduce pain.

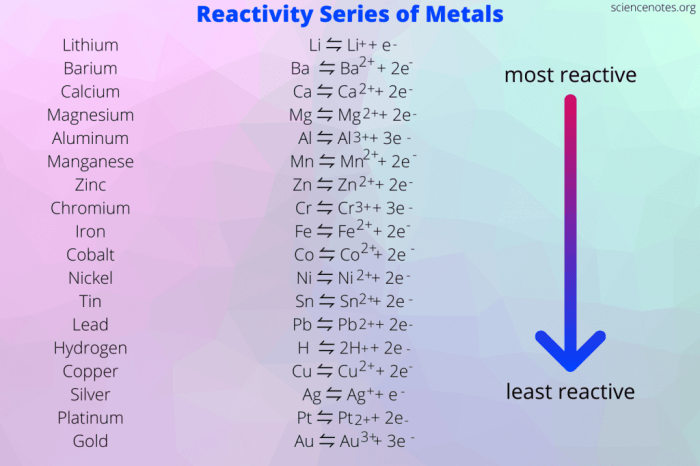

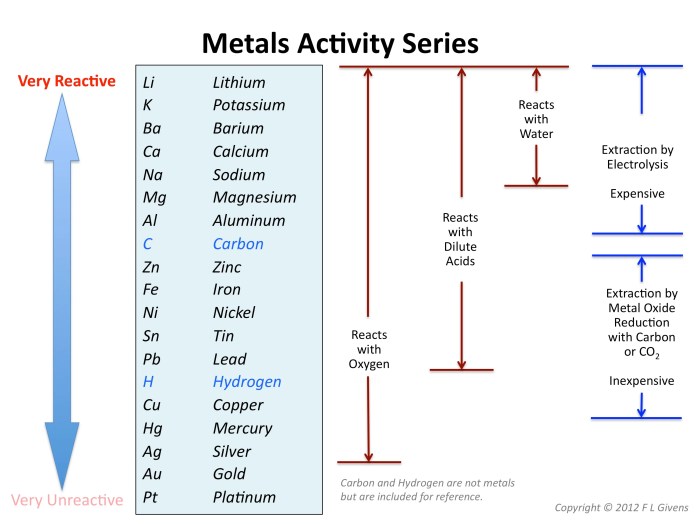

Types of Soft Reactive Metals Used in Magnets

Soft reactive metals are essential components of magnets, contributing to their magnetic properties. Various types of these metals are employed in magnet production, each with distinct advantages and disadvantages.

Iron (Fe)

- High magnetic permeability, allowing for easy magnetization.

- Low cost and widely available.

- Prone to oxidation and corrosion, requiring protective coatings.

Cobalt (Co)

- Higher magnetic strength than iron.

- Resistant to oxidation and corrosion.

- Expensive and less abundant than iron.

Nickel (Ni)

- High magnetic permeability and strength.

- Corrosion-resistant and ductile.

- More expensive than iron and cobalt.

Gadolinium (Gd)

- High magnetic moment and low coercivity.

- Used in high-performance magnets.

- Expensive and not widely available.

Production Methods of Soft Reactive Metal Magnets

The production of soft reactive metal magnets involves various processes that determine the magnetic properties and performance of the final product. These methods can be broadly categorized into powder metallurgy and casting techniques.

Powder Metallurgy

Powder metallurgy is a widely used technique for producing soft reactive metal magnets. It involves the following steps:

- Powder Preparation:The desired reactive metal, such as iron, cobalt, or nickel, is converted into a fine powder through mechanical alloying or chemical reduction.

- Mixing and Compaction:The metal powder is mixed with binders and lubricants to enhance its flowability and compressibility. The mixture is then compacted into a desired shape using a press.

- Sintering:The compacted powder is heated in a controlled atmosphere to bond the particles together and form a solid structure. This process enhances the magnetic properties and strength of the magnet.

Casting Techniques

Casting techniques involve melting the reactive metal and pouring it into a mold to create the desired shape. The two main casting methods are:

- Vacuum Induction Melting:This method involves melting the metal in a vacuum environment using an induction furnace. The vacuum reduces the formation of impurities and enhances the magnetic properties.

- Electromagnetic Casting:This technique combines melting and electromagnetic stirring to refine the molten metal. The stirring action removes impurities and promotes grain alignment, resulting in improved magnetic properties.

The choice of production method depends on factors such as the desired magnet properties, material composition, and cost considerations.

Design Considerations for Soft Reactive Metal Magnets

Designing magnets using soft reactive metals involves careful consideration of several factors to optimize their performance and meet specific application requirements.

Factors such as shape, size, and material composition significantly influence the magnetic properties of the magnet. The design process should consider these factors to achieve the desired magnetic field strength, flux density, and other performance characteristics.

Shape and Size

- The shape and size of the magnet determine its magnetic field distribution and strength. Different shapes, such as cylindrical, rectangular, or ring-shaped magnets, can be used depending on the application requirements.

- The size of the magnet affects its magnetic flux density. Larger magnets generally produce stronger magnetic fields, while smaller magnets may be more suitable for applications requiring compact designs.

Material Composition

- The choice of soft reactive metal used in the magnet significantly impacts its magnetic properties. Different metals, such as iron, nickel, or cobalt, have varying magnetic susceptibilities and saturation magnetizations.

- Alloys of these metals can be used to enhance the magnetic properties, such as increasing the saturation magnetization or reducing the coercivity.

Testing and Evaluation of Soft Reactive Metal Magnets

Testing and evaluating soft reactive metal magnets is crucial to ensure their performance meets specific requirements and standards. Various methods are employed to assess the magnetic properties, physical characteristics, and durability of these magnets.

Measurement of Magnetic Properties, Soft reactive metal used in magnets

The magnetic properties of soft reactive metal magnets are essential for determining their effectiveness in applications. The following parameters are commonly measured:

- Remanence (Br):The amount of magnetic flux density remaining in the magnet after the removal of an external magnetic field.

- Coercivity (Hc):The minimum magnetic field strength required to reduce the magnetic flux density to zero.

- Maximum Energy Product ((BH)max):The maximum amount of magnetic energy that can be stored in the magnet per unit volume.

Assessment of Physical Characteristics

In addition to magnetic properties, the physical characteristics of soft reactive metal magnets also play a significant role in their performance. These characteristics include:

- Density:The mass per unit volume of the magnet.

- Tensile Strength:The maximum stress that the magnet can withstand before breaking.

- Corrosion Resistance:The ability of the magnet to resist degradation from environmental factors such as moisture and oxygen.

Durability Testing

To ensure the reliability and longevity of soft reactive metal magnets, durability testing is conducted. This involves subjecting the magnets to various environmental conditions, such as:

- Temperature Cycling:Exposing the magnets to extreme temperature variations to assess their stability.

- Humidity Testing:Evaluating the effects of moisture on the magnetic properties and physical characteristics.

- Vibration Testing:Determining the resistance of the magnets to mechanical vibrations.

By conducting these tests and evaluations, manufacturers and users can ensure that soft reactive metal magnets meet the necessary performance criteria and are suitable for their intended applications.

Case Studies of Soft Reactive Metal Magnets: Soft Reactive Metal Used In Magnets

Soft reactive metal magnets have demonstrated remarkable potential in various applications. Here are some notable case studies showcasing their successful implementation and the challenges encountered:

Case Study 1

In the automotive industry, soft reactive metal magnets have been used in electric vehicle (EV) motors and generators. These magnets offer high energy density and low coercivity, enabling the design of compact and efficient motors. However, challenges arise in ensuring the magnets’ stability and corrosion resistance in harsh automotive environments.

To address these challenges, researchers have developed novel coating techniques and alloy compositions that enhance the magnets’ durability and performance under demanding conditions.

Case Study 2

In the field of medical imaging, soft reactive metal magnets have been incorporated into magnetic resonance imaging (MRI) systems. These magnets generate strong magnetic fields necessary for imaging. The challenge lies in achieving high field strengths while maintaining low noise and distortion levels.

Through advancements in magnet design and fabrication, engineers have optimized the shape and arrangement of the magnets, resulting in improved field homogeneity and reduced noise, leading to clearer and more accurate MRI images.

Future Trends in Soft Reactive Metal Magnets

The field of soft reactive metal magnets is constantly evolving, with new trends and advancements emerging regularly. These trends are driven by the increasing demand for high-performance magnets in various applications, such as electric motors, generators, and sensors.

One of the most significant trends in the development of soft reactive metal magnets is the use of new materials. These new materials offer improved magnetic properties, such as higher saturation magnetization, lower coercivity, and better temperature stability. Some of the most promising new materials for soft reactive metal magnets include rare-earth alloys, such as neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo), as well as amorphous and nanocrystalline alloys.

Another important trend in the development of soft reactive metal magnets is the use of new manufacturing techniques. These new techniques allow for the production of magnets with more complex shapes and smaller sizes. This is important for applications where space is limited, such as in portable electronic devices.

Potential Applications and Research Directions

The potential applications of soft reactive metal magnets are vast. These magnets are used in a wide variety of devices, including electric motors, generators, sensors, and actuators. In the future, soft reactive metal magnets are expected to find even more applications in emerging technologies, such as electric vehicles, renewable energy systems, and medical devices.

There are a number of research directions that are being pursued in the field of soft reactive metal magnets. These directions include the development of new materials with improved magnetic properties, the development of new manufacturing techniques, and the exploration of new applications for these magnets.

Essential Questionnaire

What are soft reactive metals?

Soft reactive metals are a group of elements that exhibit high reactivity and low hardness. They are characterized by their ability to form strong bonds with other elements, making them ideal for use in alloys and compounds.

Why are soft reactive metals used in magnets?

Soft reactive metals are used in magnets because they can enhance the magnetic properties of the magnet. They can increase the magnetic strength, reduce the coercivity, and improve the overall performance of the magnet.

What are the different types of soft reactive metals used in magnets?

The most common soft reactive metals used in magnets are iron, cobalt, and nickel. These metals are often alloyed with other elements to improve their magnetic properties.

How are soft reactive metal magnets produced?

Soft reactive metal magnets are produced by a variety of methods, including casting, sintering, and powder metallurgy. The production method used will depend on the desired properties of the magnet.

What are the applications of soft reactive metal magnets?

Soft reactive metal magnets are used in a wide range of applications, including motors, generators, transformers, and MRI machines.